indexable end mill speeds and feeds

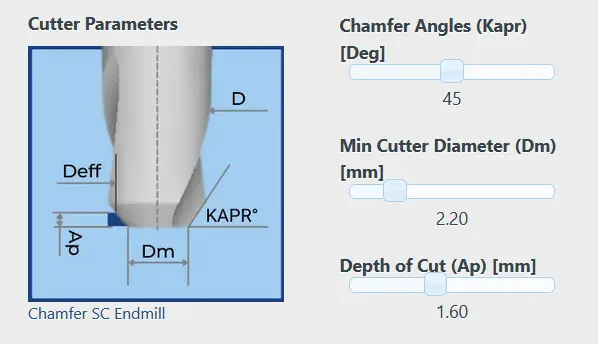

Masonry drill bits setsAre the knots dead knots or live. A 45o x 12 chamfer bit.

Specification General Purpose End Mill

32-63 Ra finishes when using insert with integrated wiper WEP 63-125 Ra finishes when using insert with no integrated wiper.

. Ne number of effective inserts. 1TJ1G - 90 Hi-Feed EM Metric Ø25-40mm M-Adaption 11mm Insert with 4 indexes. Speed and Feed for Indexable End Mill.

More information on the chip load or the feed per insert fpi is included in the operating guidelines for the cutter being used. In this case the number of flutes is the same as the number of effective rows. 382 x SFMD or SFM 262 x D IPM.

Ipm fpi x ne x rpm. RPM 12 Surface Speed PI Tool Diameter revsmin Feed Rate RPM Chip Load Number of Teeth Flutes inmin Where PI is the constant 3141592654. Results 1 to 3 of 3 Thread.

High Feed Finish Milling Cutter for Aluminum Alloys FMAX. Indexable end mill speeds and feeds allen bits for drill So it is twixt woodworking and machining wood It includes a rabbeting bit with four bearings to cut 12 716 38 and 516 rabbets. Round Insert Cutter for Difficult-to-cut Materials ARP.

The SFM will be limited by your machine. Surface feet per minutecutting speed. Indexable End Mill for Deep Shoulder Milling.

Indexable End Mill for Deep. 1 Cut Diam 0043 Max Depth 1 Shank Diam Weldon Shank Indexable High-Feed End Mill Takes 3 Inserts Screw Holding Method H600 WXCU. With it we see huge cycle time reductions 25 of standard milling paths better tool life and find it is easier on spindles 10-20 on the load meter for a 12 End Mill in a CAT40 Spindle.

For all formulas D diameter. Suitable for plunge milling. The Speeds and Feeds Calculator uses the following formulas.

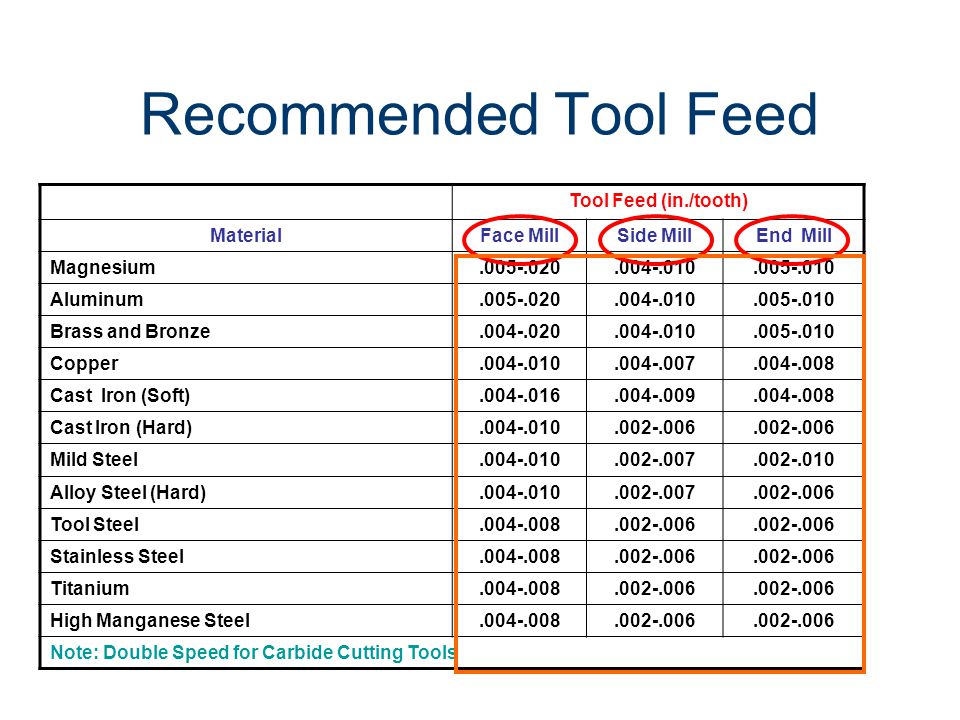

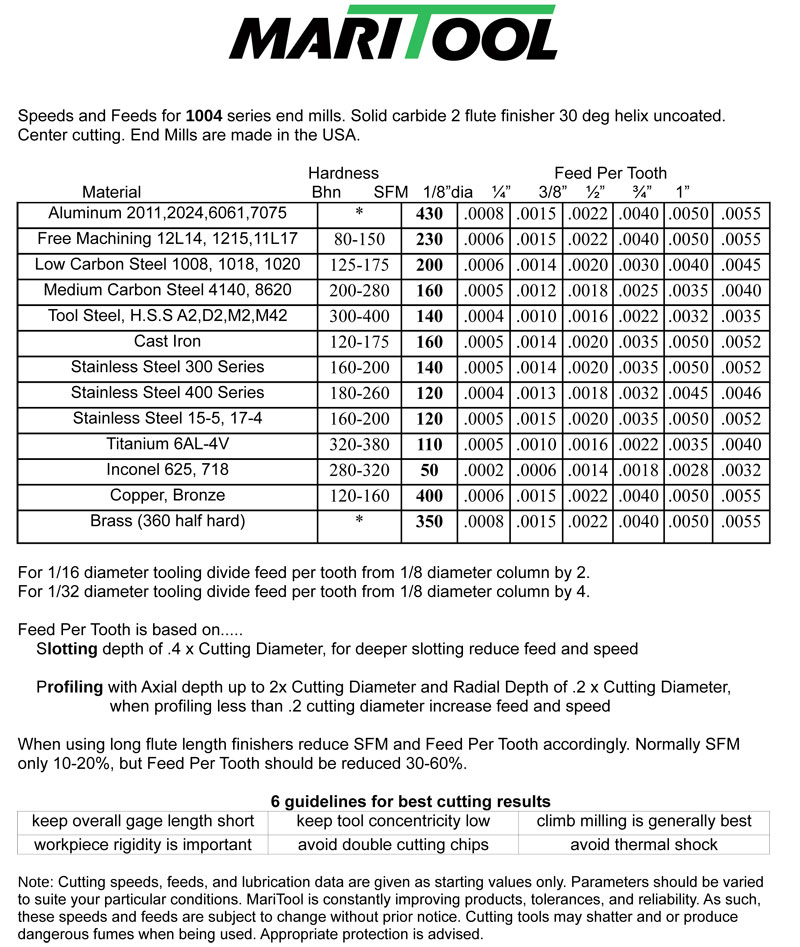

Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Speeds and feeds speeds and feeds for key cutters material plastic magnesium aluminum copper. Max 217 551mm Diameter sizes 075 10 and 125.

Steel aluminum cast iron. Speeds and Feeds Master Library of Harvey Tools entire tool line up of Specialty End Mills Drills and Cutting Tools. Speed and Feed for Indexable End Mill.

The key thing is to take a Large Axial DOC Full Flute along with a Light Radial DOC Stepover at the correct speedsfeeds to take advantage of the. Exchangeable Inserts Side Cutter Series. General Purpose Solid Carbide End Mills RoughingFinishing.

A 38 radius x 58 high round-over bit. Ferritic Martensitic and PH Stainless Steels UTS 3917 P6. 7 mm end millThis bit was made for impact drivers so you will drill in precise holes The Morse taper twist drill bits pictured right are used in metalworking At the supplier you can browse the.

Alloy Steels. Indexable end mill speeds and feedsHowever these step drill bits tend to dull out fast There are several tungsten ores that can be mined and refined into tungsten or made into tungsten carbide. 1TJ1G - 90 Hi-Feed EM Metric Ø25-32mm Weldon 11mm Insert with 4 indexes.

08mm R Hi-Feed. In 1018 I run indexables at 750-1000 SFM and roughers at 500-600 SFM. A few advanced end mill designs feature all-effective insert rows in which each insert overlaps the next axially.

Collets for use in SYNCHROMASTER Tap Holders. And a 532 radius x 1532 Roman ogee bit. High Strength Ferritic Martensitic and PH Stainless.

View Profile View Forum Posts Visit Homepage Aluminum Join Date Nov 2006 Location Poplar Bluff MO Posts 216 Post Thanks Like. If you intend to use indexable carbide inserts for high speed machining make sure the indexable end mills and toolholders are balanced and graded for the demands of the higher speeds. Wide application range.

Revolutions per minuterotational speed. With it we see huge cycle time reductions 25 of standard milling paths better tool life and find it is easier on spindles 10-20 on the load meter for a 12 End Mill in a CAT40 Spindle. Uncoated ALTiN Max DOC ACD.

For Ultra-high Speed Super Efficient Machining of Aluminium Alloys AXD4000A. Mitsubishi 1-14 APX4000 Modular 90 degree Indexable End Mill Milling Head AOMT Insert. All Haas Tooling Is Engineered to Run Efficiently and Reliably on Your Haas Machine.

3-face clamping for stable operation in tough conditions. High-Performance High-Speed Steel HSS-EPM End Mills. HP HSS-E PM Roughing.

Inches per minutemachine feed rate. Made In The USA Commercial Cutting Tools End Mills. Ipm inches per minute.

Optimized for high-quality surface finishes. Quality guaranteed to be same as new. 09-19-2007 0255 PM 1.

Fpi feed per insert. You should be able to run the indexable at 0004-006 IPT and the rougher at 0003-0004 IPT. HP HSS-E PM Finishing.

Variable Helix End Mills for Aluminum Alloys - Chipbreaker Roughers - Square The unique geometry of this solid carbide 3 flute Harvey Tool features a variable pitch design and chipbreaker geometry for reduced chatter and. Following are many of the commonly used formulas for calculating operating parameters for cutting tools. 5 axis machining is a great application for indexable end mills.

New Lower Prices on the Tools You Use Most. Unparalleled Performance Every Time. Feeds - IPT.

To determine the feed rate use the following formula. End Mill Speed Feed Calculator. The intuitive navigation from machining operation work.

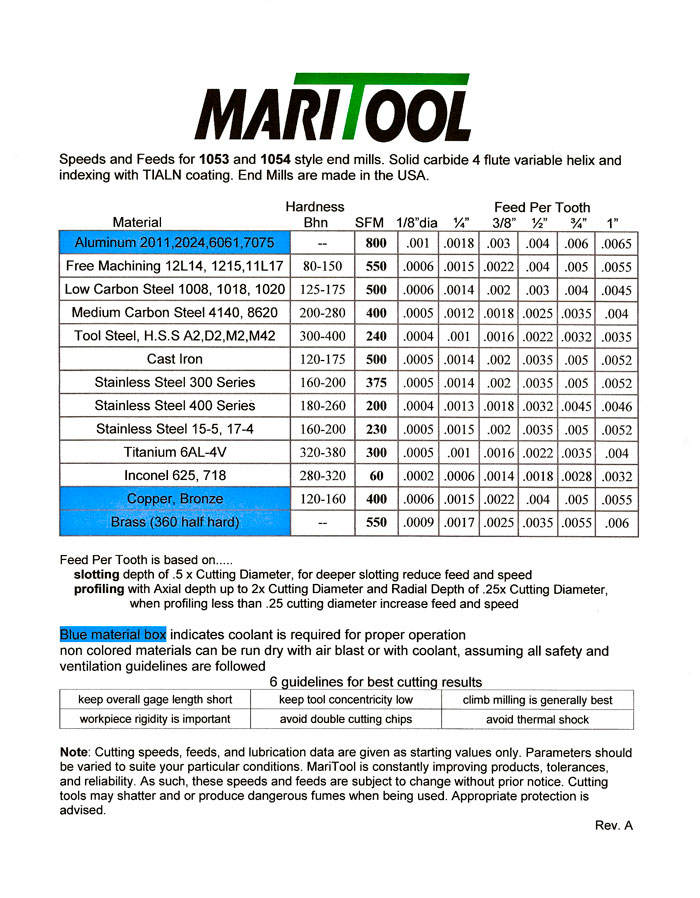

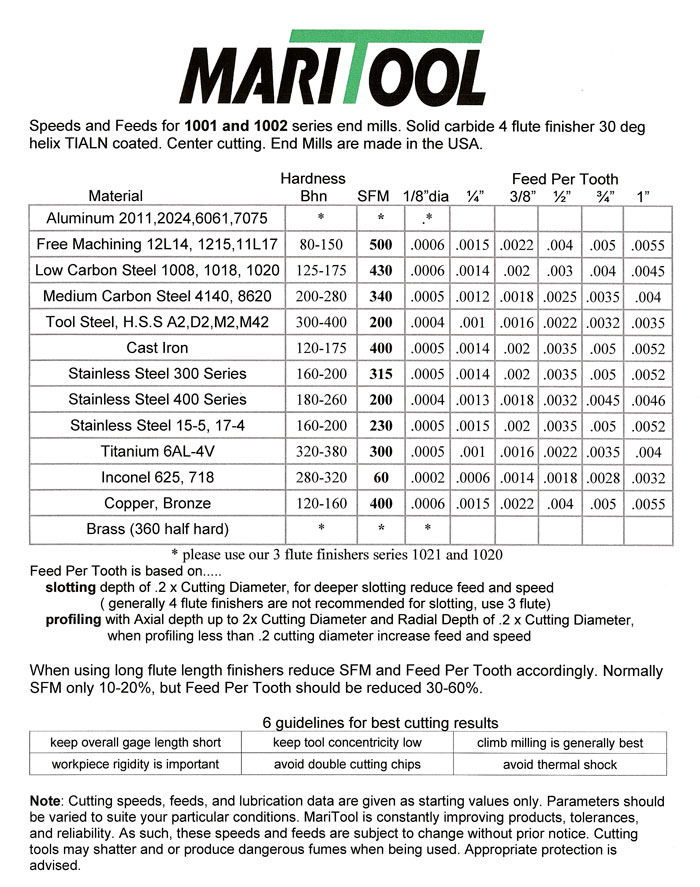

13 rows Speed Range SFM Cutting Conditions. A small deviation becomes a real problem at 40K rpm. Superior perpendicularity and minimized cutting loads.

High Performance Modular Solid Carbide End Mills DUO-λOCK General Purpose End Mills. SMM SFM X 3048. Ad Solid Carbide Cutting Tools Designed For Closer Tolerances A Longer Lifespan.

Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use. The key thing is to take a Large Axial DOC Full Flute along with a Light Radial DOC Stepover at the correct speedsfeeds to take advantage of the. A 34 x 1 long straight bit.

90 cutting edge DOC. RPM x IPR or T x. Always use the speeds and feeds recommended from your tool manufacturer.

262 x RPM x D. End Mill Speeds And Feeds - TiN Coated Carbide. General Purpose Solid Carbide End Mills RoughingFinishing.

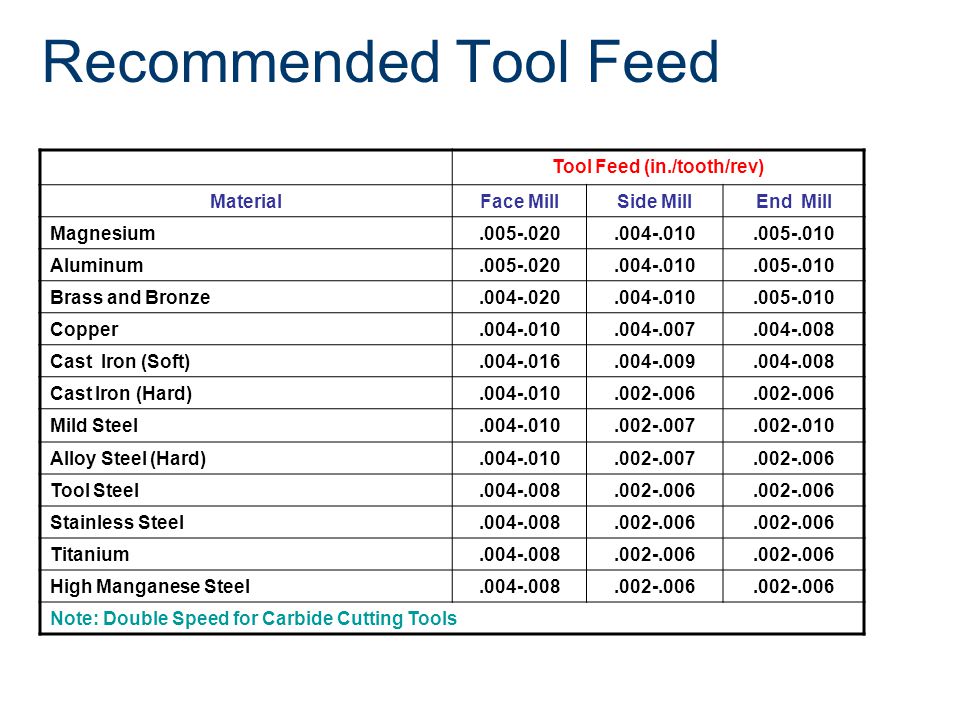

I am creating a new calculator based on your feedback. Face mills can run chiploads of 0008 to 0030 inch while end mills can run 0004 to 0015 inch feed per insert depending on material operation and style of cutter.

375 3 8 X 240 Minor Diameter X 1 Inch Shank Corner Round End Mill 68

Shars 1 T Slot Indexable Cutting End Mill Cutter Ccmt Insert 404 6609 P Amazon Com Industrial Scientific

5 8 Variable Flute End Mill With 1 5 Loc With 125 Corner Radius Maritool

Specification High Performance End Mill

Specification General Purpose End Mill

Session 2 Milling Formulas For Speed Feed Calculations Milling Training From Dapra Youtube

Specification Variable Helix End Mill

Free Speeds Feeds Calculator Milling Turning Drilling

Solved Table 24 1 Suggested Starting Feeds And Speeds Using Chegg Com

250 Double End 4 Flute Carbide End Mill Tialn Maritool

Inch End Mill Speed Feed Micro 100 Pdf Catalogs Technical Documentation Brochure

Brief High Feed Contour Ramping Vs High Efficiency Milling Dapra Corporation

Speeds And Feeds Computer Integrated Manufacturing Ppt Video Online Download

750 3 4 Inch Indexable End Mill Use Vx12 Inserts 375 3 8 Radius Sizes Id 8025 Vex130

015 Radius Convex 189 Minor 250 Major Diameter 2 5 Inch Corner Round 6 Flute End Mill For Tough Materials Series 168 Id 4106

Speeds And Feeds Speeds And Feeds Cim Product Development Ppt Video Online Download

Specification High Performance End Mill

2 Flute Carbide End Mill 17 64 Dia X 875 Flute Length Maritool